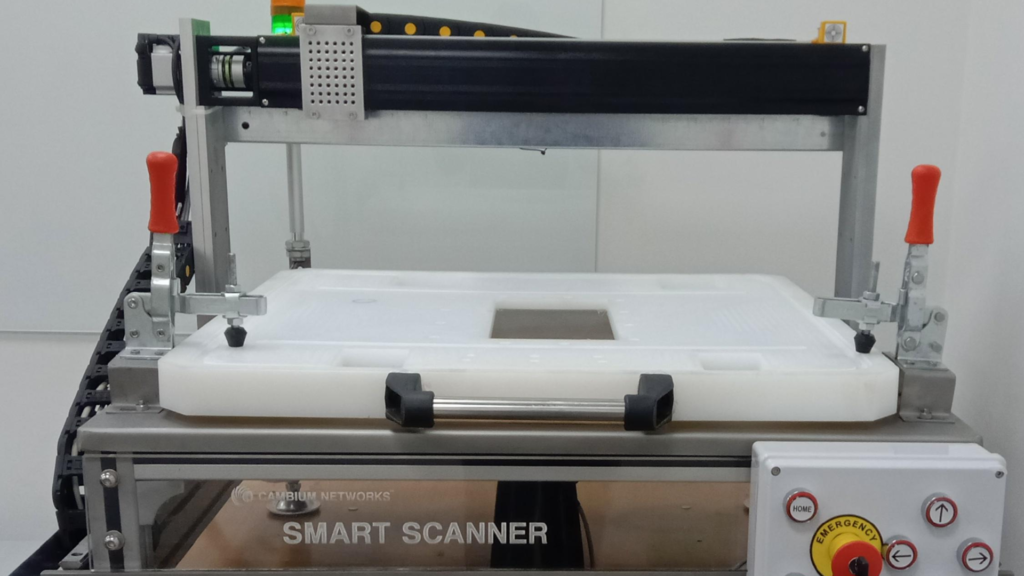

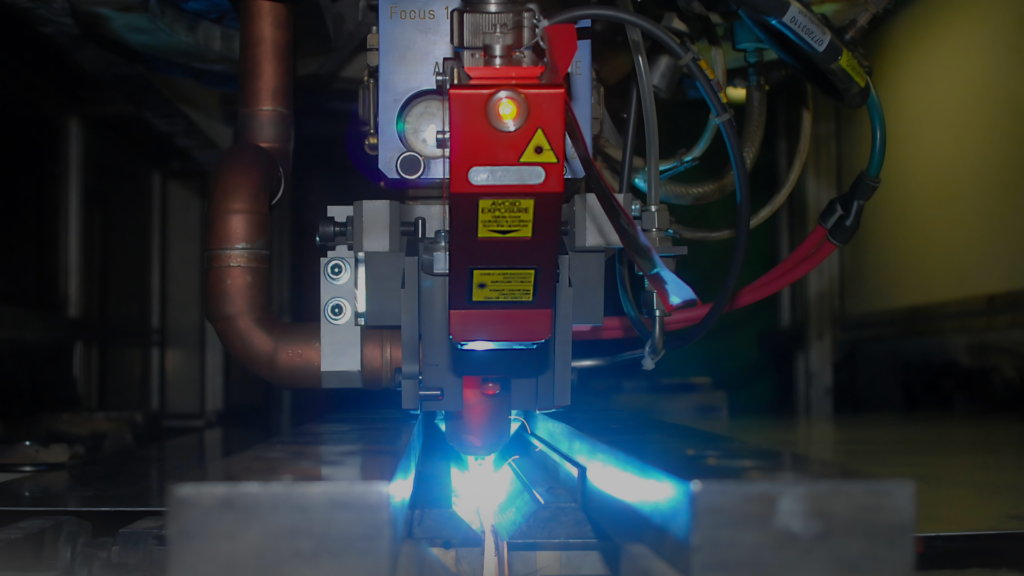

Our client, a major integrated steel plant, faces challenges with manual surface inspection of steel plates at the New Plate Mill (NPM), RSP. This process is time-consuming, error-prone, and lacks timely feedback for defect containment. To address this, our client plan to introduce a laser-based 3D camera system for automated defect identification, enhancing efficiency and accuracy.